Fostering innovation is one of the three pillars of the AFS mission. AFS has a long history of sponsoring metalcasting research and innovation. The goal of AFS research is to move the metalcasting industry forward, remove technical barriers and gaps, and improve the overall efficiency and quality of the metalcasting process.

AFS works with leading casting technical experts to discuss state of the industry, and ask leading questions such as: What would make our job better? What would we like to be able to do in 5 years, or 10 years that we cannot do now? AFS research projects help develop new technologies, improve our understanding of basic casting issues, and benchmark best practices.

AFS involvement in metalcasting research has two facets: direct funding, and partnerships.

- AFS-Funded Research

- Research Partnerships

- AFS Research Board

- Research Now Underway

- Research Success Stories

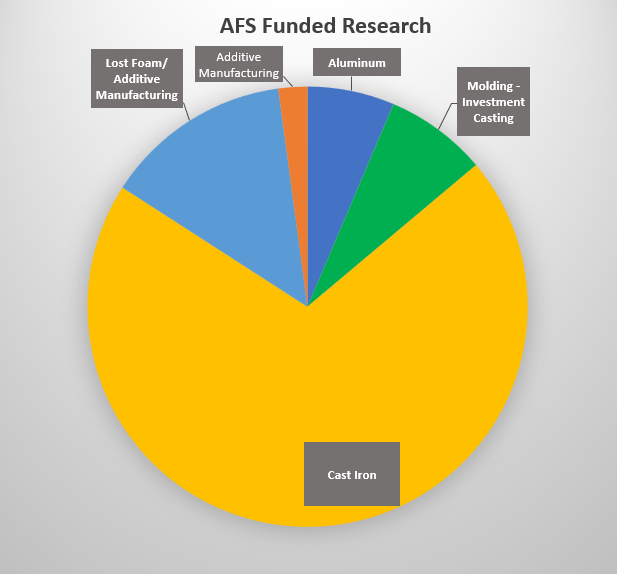

AFS-Funded Research

AFS directly sponsors research programs through a fund based on an allocation of a portion of AFS Corporate Member dues. The Research Board selects projects and provides oversight. Most research projects are developed by the AFS technical committees and their members serve as the steering committee to help monitor and direct the research toward project goals and objectives. The mix of projects varies each year, based on submissions from the divisions.

If you are interested in participating in an AFS research project or committee activity, contact the AFS Vice President of Metalcasting Technical Services Brian Began at bbegan@afsinc.org, or Assistant Technical Director of Metalcasting Services Bo Wallace at bwallace@afsinc.org.

To submit a research proposal, click here.

Chart updated February 2025

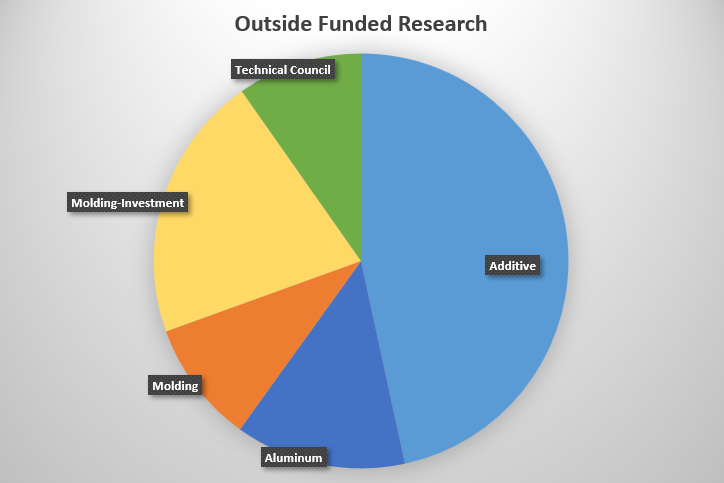

Research Partnerships

AFS is also involved in outside casting research programs. These partnerships and consortiums allow AFS to participate in additional funding and provide additional value to the industry. AFS is involved in two primary partnerships:

AMC: AFS maintains its collaboration with the American Metalcasting Consortium. The consortium is a research partnership including four metalcasting associations to promote cast metals research and infrastructure improvements to benefit U.S. military and defense needs. AMC is funded through the U.S. Department of Defense, Defense Logistics Agency, managed through the Advanced Technology Institute (ATI). Under the current (5 year) program commencing in March 2023, AFS will directly manage three projects.

AMC Emergent Metal Casting Solutions (EMCS) Program (2023-2028)

The first project focuses on investment casting and will entail three distinct objectives. The first objective will be to assess new materials, processes, or automation technologies in hopes of achieving more rapid production. The second objective will be to focus on processes and recommendations for improving the recycling of spent shell materials with associated ambition for lower cost and reduced environmental impact. The third objective is to develop best-practice data-driven design tools for risering unique Ni-based alloys where current risering capabilities require more understanding.

A second project is developing interactive digital capabilities to more rapidly transfer metalcasting technology and best practice knowledge. In this project, AFS electronic platforms such as the digital library, CADS, AFS Onlive and a new digital publications platform will be enhanced to be mobile-friendly and with enhanced navigation and improved content.

The thrust of the third project is to model the relationship between surface defects on cast metal components and casting process variables and parameters. Success would enable corrective actions to improve casting surface quality and minimize casting surface defects.

In addition, AFS will be providing technical oversight and guidance for an additional project managed by an outside investigator. This project is a continuation of a previous project that is to finalize guidelines for Nano-Reinforcing Aluminum alloys to cost-effectively increase strength without increasing weights.

ACRC: AFS is also a member of the Advanced Casting Research Center (ACRC), an industry-university research consortium focused on addressing the global foundry industry. As a member, AFS assists in oversight and selection of casting-related research programs. ACRC is located at the University of California, Irvine. ACRC is currently managing an AFS recommended program on innovative heat treating for aluminum alloys.

America Makes / National Center for Defense Manufacturing and Machining (NCDMM):

AFS is a partner in the America Makes Improvements in Manufacturing Productivity via Additive Capabilities and Techno-Economic Analysis (IMPACT) program funded through the Office of the Under Secretary of Defense, Research and Engineering Manufacturing Technology Office (OSD/R&E) and the Air Force Research Laboratory (AFRL). Under IMPACT, America Makes seeks to promote and accelerate the development and deployment of innovative, cost effective, energy-efficient AM and 3D printed technologies to meet defense and/or commercial needs.

• IMPACT 1.0: Transitioning Best Practices and Technology Improvements for Printed Sand Molds/Cores (2023-2025): AFS, along with Product Development & Analysis (PDA), LLC, will be part of a cross-functional team under the leadership of Honeywell Aerospace and will lead the efforts to support industry engagement, and the technology transfer of the technologies developed under this program as well as support efforts to characterize the baseline performance of the printed sand molds and their impact on resultant casting quality outcomes.

• IMPACT 2.0: Transitioning Best Practices and Technology Improvements for Advanced Technology Printed Sand Equipment (2024-2026): AFS, along with PDA, LLC, will be part of a cross-functional team under the leadership of Honeywell Aerospace and will coordinate efforts to support industry participation and adoption of domestic equipment and best practices and the technology transfer of the technologies developed under this program as well as support efforts to reinforce the casting supply chain with US-made and supported printed sand molds for both government and private casting buyers.

Chart updated January 2025

AFS Research Board

The AFS Research Board nominates a slate of potential new candidates in the fall meeting. The current chair contacts the candidates regarding their interest in serving, and the current research board members select the incoming member at the winter meeting. The five-year term for the new member begins in the second calendar quarter.

If you are interested in getting consideration for joining the AFS Research Board, please send a one or two page biography to bbegan@afsinc.org or bwallace@afsinc.org.

Research Now Underway

Innovation is at the heart of the AFS mission – and at the heart of innovation is research. Multiple ongoing research projects are in various stages of development. Click here to view current AFS-Funded Research.

Research Success Stories

AFS-funded research serves the entire metalcasting industry. Click below to learn more about some of our most impactful recent projects.

- Dimensional Tolerance Assessment Using 3D Printed Sand

- Welding Alloy and Process for Al-Cu Sand Castings

- PVD Coatings to Aid Release for Permanent Mold Castings

- Foundry Air Emissions Benchmarking

- Metamolding Framework and Tools for Intelligent Casting Manufacturing of Ductile Iron

- Alternative Granular Media for Green Sand Casting

- Evaluation of Alternate Aggregates for Green Sand

- Personal Air Sampling Method

- Developing Options to Produce Nanostructured Cast Alloys

- Casting Alloy Data Search Tool

- Quantifying Casting Quality Through Filling Conditions

- Turbulent Gating Effect on C89833

- Quantifying the Effect of Filling Conditions on Low Alloy Steel Casting Quality

Casting and Designing Difficult, Absorbent Lattice Structures Using 3D Printed Sand Molding