The primary ways to fuel growth of metalcasting markets are new product development, converting from fabrications, and reshoring. The American Foundry Society works aggressively to help foundries achieve success in each of these endeavors.

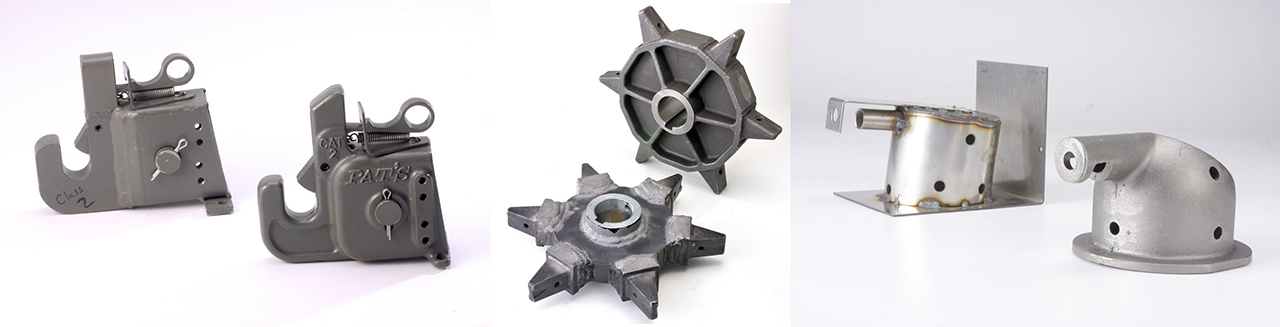

Conversions allow many manufacturers to do more than just save money. They are also achieving improved performance, reductions in weight, and shorter lead-times. Most metalcasting facilities are well-versed in redesigning parts for casting. They can share examples, and help you analyze your potential savings and benefits from conversion.

Signs Your Part Needs a New Method

- Insufficient dimensional stability

- Costly to manufacture

- Difficult to keep track of inventory

- Production volumes have grown, so the number of parts or subcomponents is unwieldy

- Requires an excess of machining

- The assembly is labor-intensive

- Too much variation occurring from assembly to assembly

- The market is ready for an improvement

When Castings Should Be Considered

- Weight reduction would be an advantage

- The assembly consists of multiple parts in the same material

- The assembly has multiple parts with the same property requirements and application demands

- The part has a complex geometry

- Multiple features can be incorporated for increased opportunity for cost reduction

- Potential benefits outweigh initial design and tooling costs

- Can another material be considered?

Competitive Advantage Through Metalcastings

Each year, many of the award-winning castings spotlighted in the AFS “Casting of the Year” competition are conversions. The cost savings, weight reductions and improved performance are extremely impressive.

AFS At Your Service

The Technical Services Division of AFS stands ready to answer basic questions related to conversions, and to refer companies to AFS-member foundries that excel in conversions. Contact Brian Began, Vice President of Metalcasting Technical Services, (847) 824-0181 x228 or bbegan@afsinc.org.